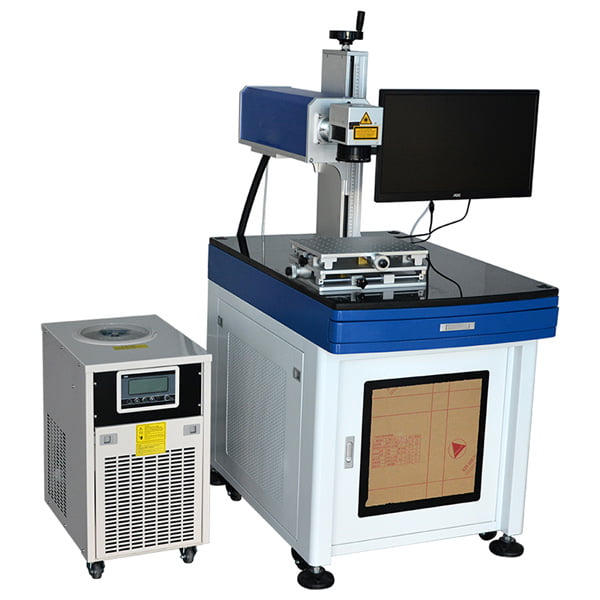

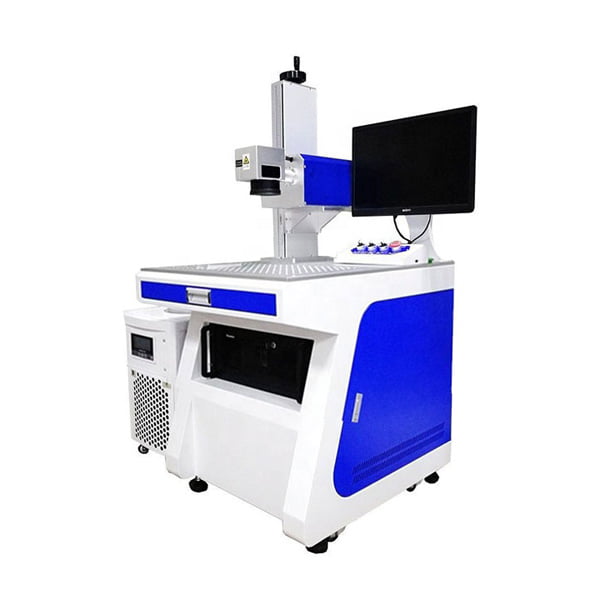

Automatic Flying Uv Laser Marking System

1. Model no.: ZE-UV

2. Laser type: 355nm uv laser

3. Laser power: 5watt, 10watt

4. Camera: CCD Visual Positioning Camera

5. Payment: T/T (optional)

6. Application: Metals, Bottles for cosmetics, pharmaceuticals, food, plastic, etc.

Automatic Visual Positioning Flying Uv Laser Marking System

1. Improved Accuracy Visual Guidance: Using High-Quality UV Laser Technology

2. Adaptable relationship of materials: the uv laser marker can mark on all metal and all plastic material

3. Quick functionality and easy-to-use interface: it can mark batch products on conveyor belts and save more production time with simple operations

4. Stable and Dependable:use the stable water chiller to make sure the uv laser is running stable

5. Advantages for the Environment: Because it doesn't produce any harmful waste products, consumables, or contaminants, the UV laser marking technique is an environmentally benign option for present production.

Product Description

Specification

| Description | Visual Positioning Flying Uv Laser Marking System |

| Marking area | 110mm*110mm or 150*150mm (optional) |

| Cooling | Water-cooling |

| UV Laser | First Grade Brand UV Laser source |

| Laser wavelength | 355nm |

| Marking speed | 400 characters per second |

| Minimum line width | 0.015 |

| Pulse width | 4-200ns |

| Machine power | 800W |

| Minmum character | 0.1mm |

Machine parts

UV Laser source

S&A Water chiller

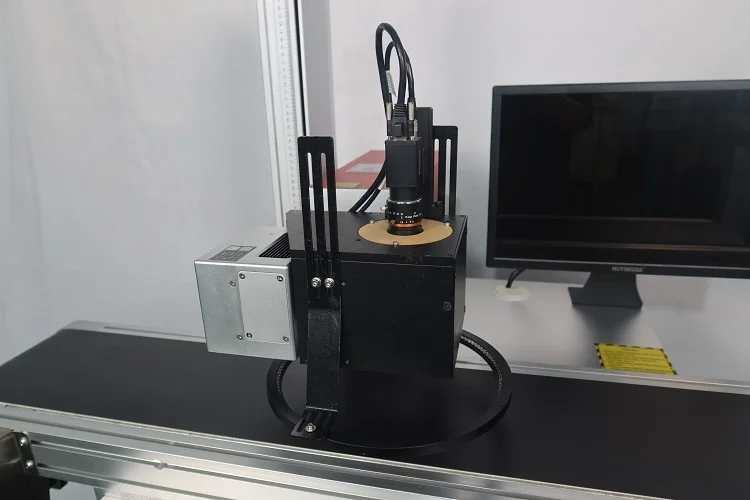

CCD camera with visual positioning UV marking

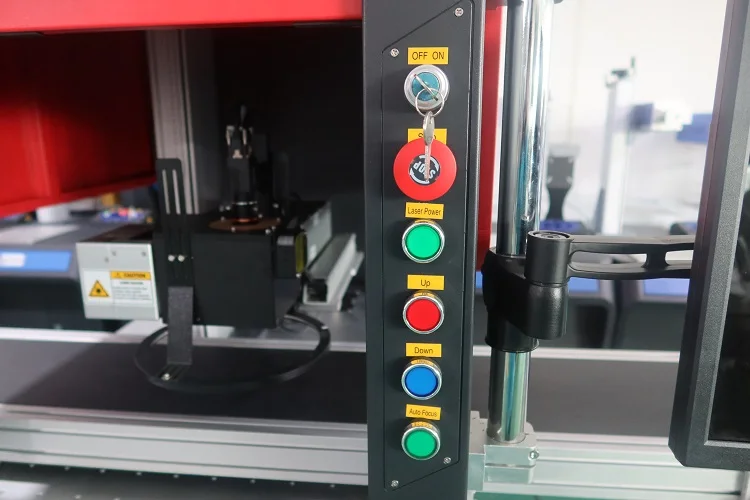

Machine Panel

Conveyor Belt

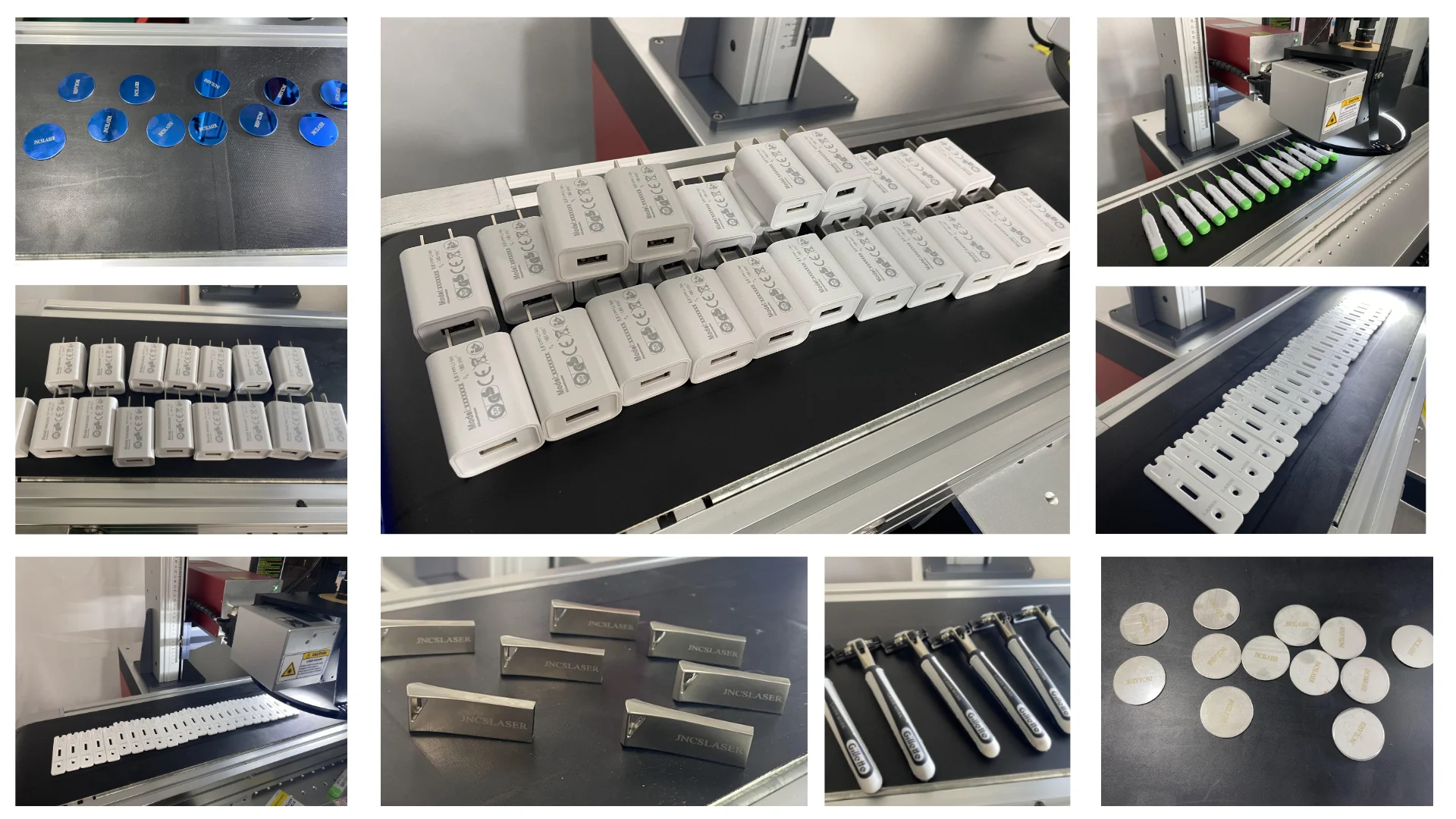

Application samples:

The system is perfect in companies including electronics, consumer goods, automobile parts, and medical devices that need precise, long-lasting markings on their products or components.

- Inner package: waterproof plastic transparent film

- Middle package: white foam, to protect the machine from shaking

- Outside package: wooded case free of fumigation

- According to different customer needs,we could send the cargo by air, sea,and railways

- The delivery lead time would be 3-5 days

Reviews

There are no reviews yet.